- English

- 简体中文

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- 繁体中文

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Ukuhlaziywa kokuhlola kokusebenza kokusebenza kwe-pneumatic ngaphansi kwama-gradients ahlukene

2025-06-19

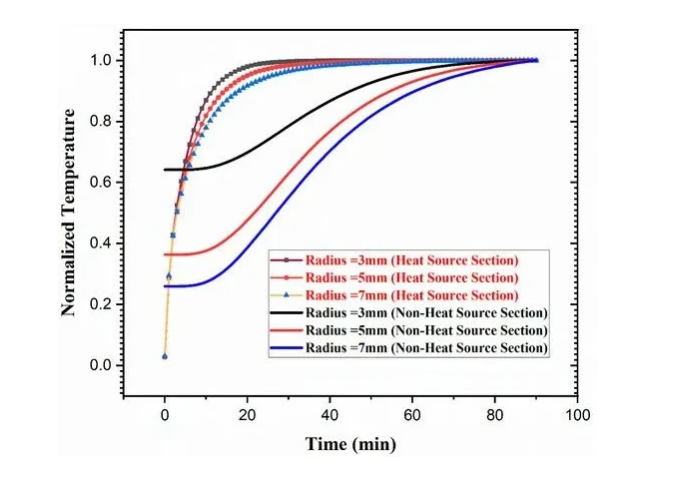

Phakathi kwa-ama-pneumatic systems, i-grafient yengcindezi iyipharamitha ebucayi echaza isimo sokugeleza kwegesi nezinhlayiya eziqinile kumapayipi. Ibonisa ngqo ukusetshenziswa kwamandla okudingekayo ukunqoba ukumelana ngesikhathi sokudlulisela futhi kunomthelela omkhulu ekusebenzeni kahle, ukuqina kanye nokusebenza kwezindleko. Ngakho-ke, ucwaningo olunzulu ekusebenzeni kohlelo ngaphansi kwe-gradients ehlukene ngokwehluka kubalulekile ekwakheni ukwakhiwa, ukwenza ngcono ukusebenza kahle, ukunciphisa ukusetshenziswa kwamandla, nokunciphisa ukulahlekelwa kwezinto ezibonakalayo. Lo mbhalo uveza ukuhlaziya kokuhlolwa kwendlela yokushintshana kwengcindezi yengcindezi ithonya ukusebenza kwe-pneumatic.

Izisekelo zokudlulisela kwe-pneumatic & gradient

Imisebenzi edlulisela imiphimbo

Ama-pneumatic systemsNgokuyinhloko sebenzisa imishini yomthombo yomoya (isb. Kususelwa ku-REATIO eqinile kanye ne-flow velocity, ukudlulisela kwe-pneumatic kuhlukaniswe ngezinhlobo ezimbili eziphambili:

- Ukudlulisela kwe-Dilicle-Phation: Isilinganiso esiphansi segesi eqinile, isivinini esikhulu segesi, izinhlayiya zimiswe e-airflow. Ilungele ibanga elifushane, ukudluliswa kwezinto eziphansi.

- Ukudlulisela okuminyene: isilinganiso esiphakeme segesi eqinile, isivinini segesi esiphansi, izinhlayiya zihambisa kuma-plugs noma izingqimba. Ilungele ibanga elide, amandla aphezulu, noma izinto ezintekenteke / ezihlukumezanayo.

Ingcindezelo ye-gradient & ukubaluleka kwayo

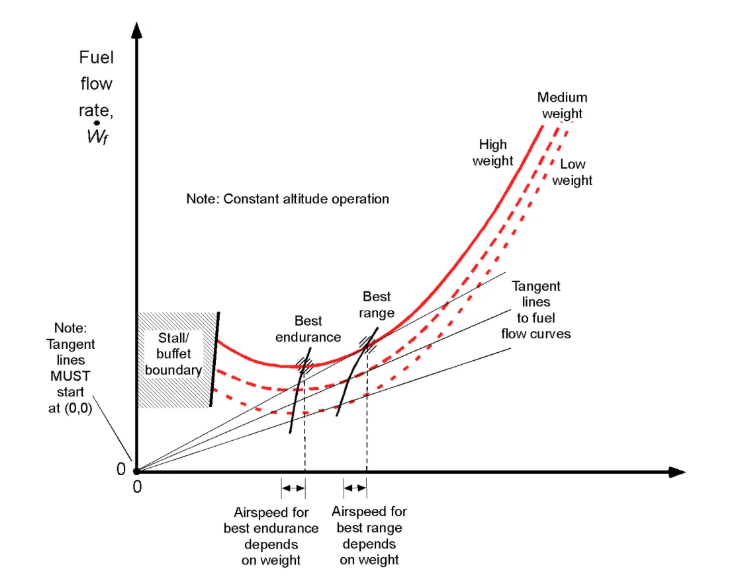

I-gradient yengcindezi (elinganiswe ku-PA / M noma KPA / m) ibhekisela ekushintsheni kwengcindezi ngobude bePipeline. Ngokudlulisela kwe-pneumatic, kukhombisa ukulahleka kwamandla ngenxa yokushayisana, amandla adonsela phansi kanye nokuqina kokusheshisa.

Imithelela ebalulekile ye-Pressuent:

- Ukusetshenziswa kwamandla: Ama-gradients aphezulu adinga amandla amaningi kusuka kuma-blowers / ama-compressors.

- Ukuqina kokugeleza: Ama-gradients afanele aqinisekisa ukuhamba ezinzile (e.g., ukugeleza okuminyene kwe-plug). Kuphansi kakhulu → ukuvalwa; Kuphezulu kakhulu → Ukugqoka ngokweqile nokungcola kwamandla.

- Ukudlulisa umthamo: Ngaphakathi kwebanga elithile, ukwandisa i-gradient kuthuthukisa ukukhishwa kwezinto ezibonakalayo.

- Umonakalo we-Material & Pipeline: Ama-gradients amaningi akhulisa ukwehla kwezinhlayiyana kanye nokugqoka kwepayipi.

Izindlela Zokuhlola & Amametro Wokusebenza

Ukusetha kokuhlola

Ukudlulisela okujwayelekile kwe-pneumatic test rig

- Ukuhlinzekwa komoya (ama-blowers, ama-compressors)

- Uhlelo lokudla (i-Screw feeders, ama-rotary valves)

- Ukudlulisela ipayipi (obala ukubonwa kokugeleza)

- Isihlukanisi esiqinile segesi (izivunguvungu, izihlungi zesikhwama)

- Isisindo nokuqoqwa (ukulinganisa izinto ezibonakalayo)

- I-SensOrs & DAQ System:

- Ingcindezi transcucers (ama-gradients endawo / womhlaba)

- Amamitha we-Flow (ivolumu yegesi)

- Isilinganiso se-Velocity (LDV, PIV)

- Izinzwa zokushisa

Izinkomba Zokusebenza Ezibalulekile

- Ingqikithi yethonya (ΔP inani ) = isigaba segesi (Δp g > g

- Ingcindezelo ye-gradient (ΔP / L) - Ipharamitha Coloc (PA / M)

- Izinga eliqinile lokugeleza kwesisindo (m s ) - kg / s noma t / h

- Isilinganiso segesi eqinile (μ) = m s / m g

- Ukusetshenziswa kwamandla (e) = Ukufakwa kwamandla / m s

- I-Particle Breakage & Amanani Okugqoka Amapayipi

Okutholakele Okusemqoka

- Ingcindezi ye-gradient vs. edlulisa umthamo

- Ukwanda kwe-gradient (nge-velocity ephakeme ephakeme / ukulayisha okuqinile) kuqinisa ukukhishwa kwezinto, kepha kungenjalo ngokuqondile.

- Isibonelo: Okwe-2mm Plastic Plastice Pellets kumaphayiphu we-100mm, ukukhulisa i-ΔP / L kusuka ku-100 kuye ku-300 pa / m kukhuphuke ngokudlulela kusuka ku-0.5 kuya ku-2 t / h. Okunye kwanda ukuncipha okunciphayo.

- Isigaba se-DICUTUTE-SGATE: I-Gradients Accients Werce Parkling; Ama-gradients afanele aqinisekisa ukumiswa okuzinzile.

- Isigaba esiminyene: ama-gradients angaphansi kuka-150 pa / m abangele ukuvalwa; 250-350 pa / m kugcinwe i-plug eqinile yokugeleza; > Ama-450 Pa / PA aphazamise ama-plugs abe yi-Dlule Flow.

- I-curve enomumo yejika i-gradient (ΔP / L) kanye nokusetshenziswa kwamandla (e).

- Isibonelo: Uhlelo lwebanga olude luthola ukusetshenziswa kwamandla okuncane (5 kWh / t) ku-ΔP / L = 50 KPA.

- Ama-gradients aphezulu (e.g., 400 vs. 200 pa / m) iphindwe kabili i-Glass Bead Breakage (0.5% → 2.5%) nokugqoka kwepayipi.

- Ukushintshashintsha kwengcindezi (ukuhlaziya i-FFT) Ukuqina kwesiginali (e.g., ubungozi obubolayo).

I-Engineering noptimign imfighting

- Design & Ukukhetha: Qondanisa amabanga amisiwe ezintweni ezibonakalayo (inhlangano, ukudala) kanye nezidingo zebanga / ukuphakama.

- Ukuhleleka kokusebenza: Lungisa amanani entengo emoya / okuphakelayo ukuze ulondoloze i-ΔP / L endaweni ethi "SOST SO SPOT" ukuze usebenze kahle.

- Ukulawulwa kwe-Smart: Izinzwa ze-IOT + Izilongi zePid eziqhutshwa yi-AI zokwenza kahle kweziqu zesikhathi sangempela.

- Gqoka ukunciphisa: Sebenzisa amapayipi anama-ceramic noma ama-bends aqinisiwe ngezinto ezihlukumezayo.

- Ukulungiswa okuqondene nezinto ezibonakalayo: Faka i-Flow AIDS noma ukuguqula ubulukhuni bepayipi ukuze bashintshe izidingo ze-gradient.

Isiphetho & Ukubuka Kwesikhathi Esizayo

Lokhu kuhlaziya okuhlola kukhombisa ukuthi ingcindezi yengcindezi ihlose kangakanani ithonya ukusebenza kahle kwe-pneumatic, ukuqina, nezindleko. Intuthuko yesikhathi esizayo ekulawuleni kokuqagela okunamandla okusebenza nge-AI kanye nezinhlelo zesikhathi sangempela sesikhathi esithembisa ukwenziwa kabusha, ukushayela okuluhlaza okotshani, ukuhambisa izixazululo zezimboni ezinobuhlakani.

Mayelana ne-Yinchi

I-Shandong Yinchi Entental Protection Equepper Co, Ltd.(I-yinchi) ngokukhethekile kuthuthukiswaama-pneumatic systemskanye nezixazululo zezinqwaba zokuphatha izixazululo. Imiklamo yethu ye-R & D-eqhutshwa iqinisekisa ukusebenza kahle kwamandla, okuphansi okugqoke kahle kuzo zonke izimboni.

Xhumana nathi:

📞 + 86-188753147775 | ✉ sdycmachine@gmail.com